Refrigerant is the working fluid used in the refrigeration cycle of air conditioning systems and heat pumps, and in most cases undergoes repeated conversion from liquid to gas. The working principle of the refrigeration cycle is that a liquid expanding into a gas extracts heat from the surrounding substance or area. Refrigerants evaporate or "boil" at much lower temperatures than water, which allows them to extract heat at a more rapid rate.

Refrigerators and air conditioners play an important role in the domestic and industrial sectors. They also contribute to environmental issues such as ozone depletion and global warming. Since the beginning of refrigeration technologies, different refrigerants have been developed. Currently, the introduction of new refrigerants to the market depends on various factors such as harmlessness, resilience, and environmental issues.

The Impact of refrigerant is classified using two measurements; ODP and GWP.

What is ODP & GWP ?

The ODP (Ozone Depletion potential) is the ratio of the capacity of a substance to degrade ozone, to that of CFC-11 (chlorofluorocarbon-11). CFC – 11 therefore has an ODP value of 1 while HCFC-141b, for example, has an ODP of 0.11, and is 10 times less degrading than CFC-11. Other substances, such as pentane, have an ODP of zero, that is, they do not damage the ozone layer. The lower the ODP value, the better the refrigerant is for the ozone layer and the environment.

GWP (Global Warming Potential) is the substance's ability to trap heat in the atmosphere compared to that of carbon dioxide. The more heat the gas traps, the greater its potential to contribute to global warming. A GWP is calculated over a specific time interval, commonly 20, 100, or 500 years. CFC-11 has a 100-year GWP of 4,250, HCFC-141b has a GWP of 725, HFCs have a GWP of up to 1,640, and pentane has a GWP of less than 5. The higher the GWP value, the more infrared radiation the gas will tend to absorb during its lifetime in the atmosphere, leading to more heating. Therefore, the higher the GWP score, the more harmful the refrigerant is believed to be to the environment.

First-generation refrigerants

First-generation refrigerants used in the 19th century was only the beginning of the mechanical cooling process. Most first-generation refrigerants like water and carbon dioxide are natural.

Water was one of the most widely used refrigerants in those days. Carbon dioxide was an effective refrigerant used for a long time, but it was the main contribution of ozone layer depletion, because of this they were completely replaced with CFCs (Chlorofluorocarbons). There was also ethyl ether which was the most decent refrigerant due to its less weight and its low melting point at normal temperature. Even though first-generation refrigerants were eco-friendly, they were either flammable or toxic or both. Some were so reactive that they resulted in dangerous accidents most of the time.

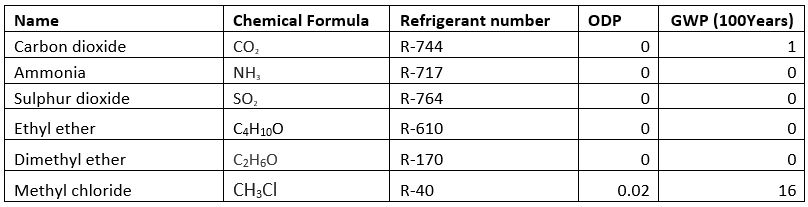

Some first-generation refrigerants and their features are discussed below.

Table 1. First generation refrigerants

Taking a look at the first-generation refrigerant list, we can see that ODP and GWP is very small for all compounds, which means they were not harmful to the environment. But increased development and requirements failed to meet desired freezing effect and hence the second-generation refrigerants came into the picture.

Second generation refrigerants

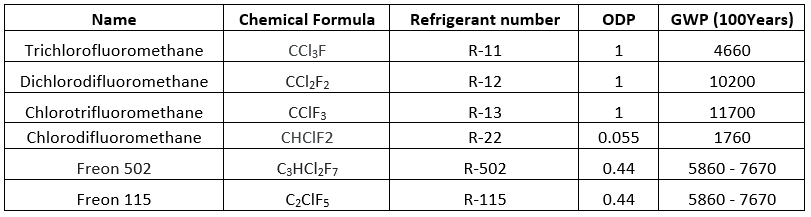

The main feature of the second-generation refrigerant was that it converts to chlorofluorocarbons for safety and durability because they were developed to counter the lack of safety and durability of the first-generation refrigerants. Chlorofluorocarbons and changes in hydrocarbons have a major impact on the flammability and toxicity of refrigerants. CFCs are non-toxic, non-flammable as well as non-reactive. It is very stable that only ultraviolet rays can break it making it suitable for a variety of applications. R-11 and R-12 were two of the most common second-generation refrigerants. The R-11 is really an excellent refrigerator and is mostly used for refrigeration and air conditioning applications. It is non-toxic, non-flammable, and non-explosive. The only problem with second-generation refrigerants is that they contribute significantly to ozone depletion and global warming.

Some second-generation refrigerants and their features are discussed below.

Table.2. Second generation refrigerants

The ozone depletion problem created the need for third-generation refrigerants, which are modified second-generation refrigerants.

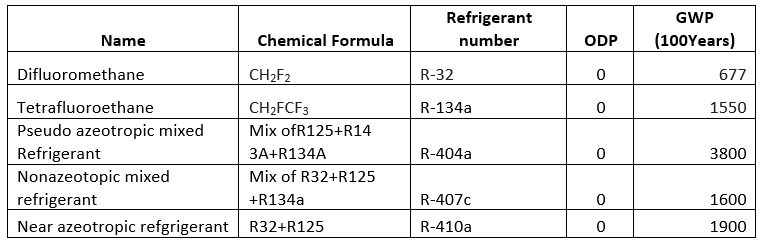

Third generation refrigerants

Third-generation refrigerants were developed to reduce the risk of global warming and ozone depletion. This is a new group of refrigerants based on the hydrochlorofluorocarbon (HCFC) and hydrofluorocarbon (HFC) chemicals. In addition to their low GWP, their main advantage is that they can be used with existing refrigeration system designs. It's good for the industry and its customers, but it's still a fluorine gas. The government is trying to encourage developers of refrigeration systems to use low-impact third-generation refrigerators. The third generation of refrigerants contains chemical groups such as hydrofluorocarbons (HFCs) that do not damage the ozone layer because it was a natural hazard at the time. However, the next generation of refrigerants is needed, as the effects of refrigeration leaks are evident in global warming and climate change.

Table.3. Third generation refrigerants

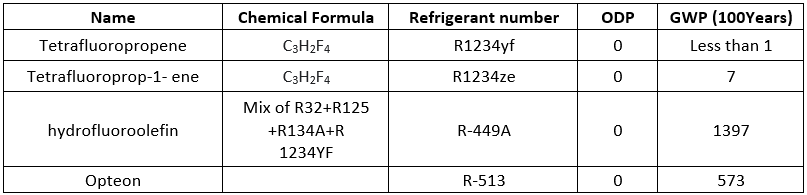

New generation refrigerants - Future of refrigerants

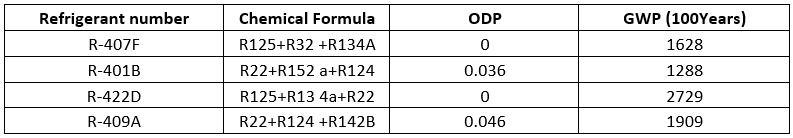

These new generation refrigerators while better than previous generations, presents more environmental concerns. This set of refrigerants is a transitional refrigerant, and can still be called HFC / HCFC partially chlorinated refrigerants. Some second-generation refrigerants are on the verge of being shut down for industrial use due to environmental issues, And these new generation refrigerants appear to be the best option for the future as they have very low ODP and GWP. They are classified as having low global warming potential and HFC / HCFC Blend.

Table.4. New generation refrigerants

Table.5. HFC/HCFC blend refrigerants

These refrigerants are a great alternative to second and third-generation refrigerators with high GWP. They are not only economical but also beneficial for a safe environment. The future refrigeration system will be based on further research on modifications and optimal use of natural refrigerants.

Each refrigerant has different characteristics, and there is no one-size-fits-all solution. The development must access to four key factors:

1. Environmental impact

2. Safety

3. Cost-effective

4. Energy efficient

.png)

No comments yet. Start a new discussion.