Vapour pressure, boiling point & NPSH

The pressure exerted by vapour present above a liquid surface is known as vapour pressure. The boiling point of a liquid is the temperature at which the substance changes from a liquid to a gaseous phase. At this point, the vapour pressure of the liquid is equal to the pressure applied to the liquid.NPSH or Net Positive Suction Head) is defined as the difference between the fluid head at the centre of the impeller and the vapour pressure of the fluid. The purpose of the NPSH is to identify and eliminate operating conditions that may lead to the evaporation of the liquid as it enters the pump.

NPSHa (Net Positive Suction Head Available) is a measure of how close a liquid is to converting into a vapour and cavitating. NPSHr (Net Positive Suction Head Required) is the absolute pressure that must be present in a liquid for a pump to avoid cavitation while pumping the liquid. It is specified by the vendor or manufacturer.

The requirement is that, NPSHa > NPSHr. Otherwise (if NPSHA < NPSHr) the pressure at the pump inlet will drop to that of the vapour pressure of the fluid being moved and the fluid will boil. When the pressure rises again, the resulting gas bubbles burst inside the pump. These implosions occur in the impeller, which can lead to pump damage and reduced efficiency.

Temperature dependence of vapour pressure

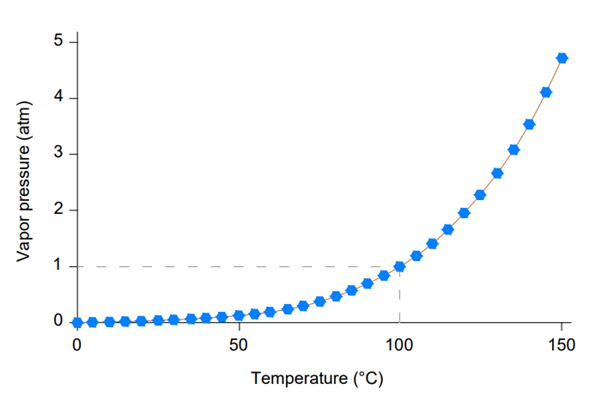

At higher temperatures, more molecules have the energy needed to escape from the liquid. At lower temperatures, fewer molecules have the energy needed to escape from the liquid. As the temperature of liquid increases, so does its vapour pressure. Conversely, as the temperature decreases, the vapour pressure decreases. Fig.1 & table 1 illustrate the temperature dependence of vapour pressure of water.

Fig.1- Temperature dependence of vapor pressure of water

|

Temperature (oC) |

Pressure |

Temperature |

Pressure |

|

0.0 |

0.61 |

23.0 |

2.81 |

|

5.0 |

0.87 |

23.5 |

2.90 |

|

10.0 |

1.23 |

24.0 |

2.98 |

|

15.0 |

1.71 |

24.5 |

3.10 |

|

15.5 |

1.76 |

25.0 |

3.17 |

|

16.0 |

1.82 |

26.0 |

3.36 |

|

16.5 |

1.88 |

27.0 |

3.57 |

|

17.0 |

1.94 |

28.0 |

3.78 |

|

17.5 |

2.00 |

29.0 |

4.01 |

|

18.0 |

2.06 |

30.0 |

4.25 |

|

18.5 |

2.13 |

35.0 |

5.63 |

|

19.0 |

2.19 |

40.0 |

7.38 |

|

19.5 |

2.27 |

50.0 |

12.34 |

|

20.0 |

2.34 |

60.0 |

19.93 |

|

20.5 |

2.41 |

70.0 |

31.18 |

|

21.0 |

2.49 |

80.0 |

47.37 |

|

21.5 |

2.57 |

90.0 |

70.12 |

|

22.0 |

2.64 |

95.0 |

84.53 |

|

22.5 |

2.72 |

100.0 |

101.32 |

Table.1: vapor pressure of water at different temperature

Effect of vapour pressure on pump performance

The effect of cavitation is the noise and vibration in the first stage. If the pump operates at the cavitation conditions for enough time the following can occur.

• Marks on the impeller blades and on the internal volute casing wall of the pump due to pitting.

• Premature bearing failure

• Shaft breakage and other fatigue failures in the pump

• Mechanical seal failure

These problems can be caused by;

• A reduction of pressure at the suction nozzle

• An increase in temperature of the pumped liquid

• Separation and reduction of the flow due to changes in the viscosity of the fluid.

• An increase in the velocity of the flow of fluid.

• Undesirable flow condition caused by obstructions or sharp elbows in the suction piping.

The focus should be on resolving the cavitation problem by increasing the external pressure on the fluid or decreasing its vapour pressure

The external pressure could be increased by;

• Increasing the pressure at the pump suction

• Reducing energy losses (Friction) at the entrance of the pump.

• Using a larger pump

The vapour pressure of the fluid is decreased by;

• Lowering the temperature of the fluid

• Changing to a fluid with lower vapour pressure

Types of cavitation

There are five recognized types of cavitation

• Vaporization cavitation

• Internal recirculation cavitation

• Vane passing syndrome cavitation

• Air aspiration cavitation

• Turbulence cavitation

Vaporization cavitation

Vaporization cavitation represents about 70 percentage of all cavitation. At what temperature does water boil? Well, it depends on the pressure. If the temperature is high enough, the water will boil. If the pressure is too low, the water will boil. Under the right conditions, the liquid may boil or evaporate into the impeller's eye. When this happens, we say that the pump is experiencing vaporization cavitation. To prevent this type of cavitation, the NPSHa in the system must be higher than the NPSHr of the pump.

A good suggestion to prevent vaporization cavitation is:

NPSHa > NPSHr + 3 ft or more safety margin

To prevent this type of cavitation damage:

1. Lower the temperature of the liquid.

2. Raise the liquid level on the suction side.

3. Changing the pump.

a) Reduce the speed of the pump.

b) Increase the diameter of the impeller eye.

c) Replace with two lower-capacity pumps in parallel.

d )Use a booster pump.

Internal recirculation

This cavitation is the result of low flow conditions where the discharge flow of the pump is restricted. The liquid is forced to recirculate from high-pressure zones in the pump and to low-pressure zones across the impeller. This type of cavitation originates from two sources, first, the liquid is circulating inside the volute of the pump at the speed of the pump and rapidly overheats, second the liquid is a force to pass tight tolerances at a very high speed.

To prevent this type of cavitation damage:

• Check the downstream filter for any debris or accumulation.

• Check the discharge valve and make sure it is open and not closed.

• Make sure the check valve is installed properly. A common mistake during installation is to attach this valve to the rear.

Vane passing syndrome

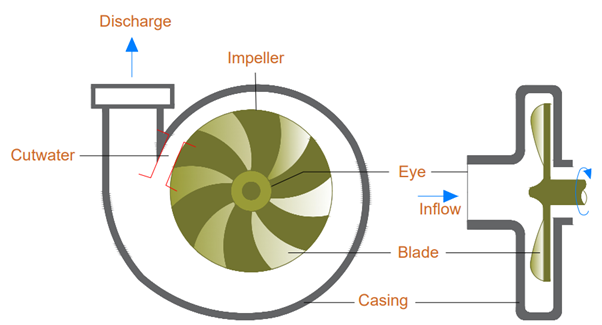

This type of cavitation can exist when the blade tips at the outside diameter of the impeller are passing too close to the cutwater of the pump casing. Make sure the gap between your impeller and its housing (cutwater clearance) is 4% of your impeller diameter. Fig.2 illustrate cutwater clearance.

Fig.2 Cutwater clearance

Air aspiration

Turbulence cavitation

Preventive steps

• Increase the pump suction line size to reduce turbulence• Make sure you do not exceed the performance guidelines of your pump manufacturer.

.png)

No comments yet. Start a new discussion.