Cooling Systems For Dairy Cattle

A blog on cooling systems for dairy cattle.

Like humans, cows need a certain temperature to maintain their health in good conditions. In dairy farms if the temperature becomes too high, it can affect the milk production and fertility of the female cows. The human body uses homeostasis to maintain its temperature; on a hot summer day, whenever we feel overheated, we may jump into the shower or the pool. Similarly, cows pant to cool themselves, but cows do not sweat like we do. And in a cattle farm, they need assistance to maintain their temperature within the perfect range and avoid heat stress. This article introduces you to the various stages of heat stress that cows may face and innovative cattle cooling systems that can prevent this.

Heat stress

Heat stress can negatively and significantly affect the reproductive and production potential in dairy animals. The body temperature of cows are around 38.5 degrees Celsius. At 39C, the cow is under moderate to high thermal pressure. When a cow's body temperature is between 39.2 and 39.5 degrees Celsius, it is under high thermal pressure and when it reaches 40 degrees Celsius, the cow is considered to be under "extreme heat pressure". Heat stress in beef cattle can be detected by homeostatic mechanisms such as suffocation, sweating, urination and behavioural changes such as decreased activity, increased water consumption, and reduced feed intake.

Keeping your cows cool is key to successful dairy farming. Cooling the cows is essential for dairy farms as heat stress can lead to reduced milk production, further disease, and reduced calf birth rate. According to research from the University of Florida, heat stress can reduce the milk production of dairy cows by 15 to 20 percent. Temperature above 21 degrees C will cause them to overheat. The cows’ natural resistance to high heat causes their appetite to be suppressed. Reproductive efficiency also suffers during thermal stress, and breastfeeding is delayed and costly to regenerate.

Implementing proper breeding programs and cooling strategies at farms can help minimize some of the negative effects of heat stress. Global warming will have significant economic consequences for both producers and consumers.

Signs of heat Stress

- Animal moves to shade

- Water intake enhanced while feed intake reduced

- Prefers standing than lying down

- Increased respiration rate, body temperature

- Increased production of saliva

- Open-mouth panting

Strategies to prevent heat stress in cows in a farm

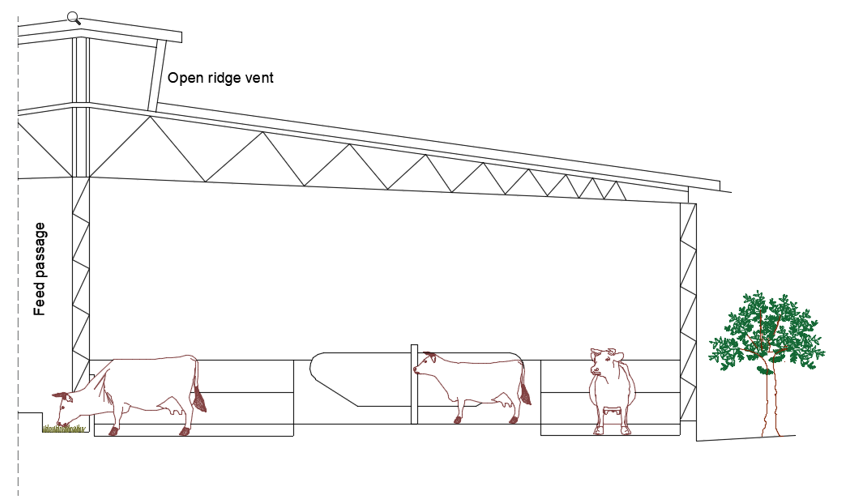

1. Shelters for cooling cows

The first and most basic step is to provide shelter and block solar radiation. The trees provide effective shade but usually they die quickly when surrounded by cows due to friction and soil turbulence. Trees are also a dangerous place for cows during a thunderstorm. A portable shade cloth is a good alternative. 2-inch diameter pipes can be used for the frames, providing hooks to move the fabric. High density shade clothes are best for effective share; they’re usually kept 12 feet from the ground.

Another option is to use permanent shadow structures. They should be 16 feet high, dirt-free, and have mounts to promote drainage. The structure should be arranged on a long north-south axis so that the cows can follow the shade outside the roof and preferably dry the dirty floor. Fans and foggers can be added to increase cooling efficiency.

2. Cooling your cows with cattle cooling systems

Cattle cooling systems have been found to be incredibly good at keeping cows cool and fertile all summer. The idea is to cool your cows as if they would be with a good rain and a pleasant breeze. As you might expect, this is a complicated process because the water droplets must be accurate in size to achieve maximum efficiency. In addition, maintaining the right wind speed is also essential.

There are many components to a cattle cooling system. The first one is the set of fans within the barns. Natural ventilation is important in feeders and free-stall barns; it removes stale and warm air. But it does not provide adequate airflow throughout the cow's body on days of high heat, high humidity, and low wind speed. Fans are needed to increase airflow throughout the body of the cow. Another important component is water. The value of water for the comfort of the cow cannot be underestimated. It is useful to remember that in situations that present a high risk of heat stress, water is important not only for drinking but also for helping the cows expel excess body heat.

A smart cattle cooling system should also ensure adequate space for cows. Cows are better off when there is more space, because, like us, closer they are the more heat surrounds them, making it more difficult for them to manage their body temperature.

How does a cattle cooling system work?

We first lead the cows first to the area where showers take place. Effective cooling requires the following factors: First, your cows need at least 1.5 to 2 meters of space. Spread the water evenly and in large drops. The use of fog may temporarily cool the cows, but the use of large drops evenly will allow water to penetrate the cow's skin, providing a prolonged cooling effect. Remember that showers should be the right size for the cows, and the water droplets should be large enough. This is to ensure that only the backs and sides of the cows are moist.

The next step is to dry them. The drying process should take place at high wind speeds 2m / s. In the cooling shed, sprinklers are installed to distribute the water evenly. To dry the cows, use circular fans or helicopter fans. If the cow's parts are still wet after the waiting room, their skin may become infected as they create the perfect environment that promotes fungal growth, so it is important to dry the cow's body after watering.

The waiting room is the place where the cows are kept before milking. The cows are milked three times a day. So, keep the cows cool by doing this cycle thrice every day. Depending on the weather, you may do this more often and add a few more cooling cycles.

There are two types of evaporative cooling systems available:

• Sprinkler systems water the cows and then blow fans into the cows' bodies to evaporate the water and cool the cows. These systems work very well, but sometimes put a lot of water on the floor. In addition, damp floors can cause foot problems. Floors should be smooth for skid resistance to reduce footwear.

• High pressure fogging systems cause water to evaporate between the fan and the cow, thus cooling the air before blowing it across the cow. These systems waste less water and dry out the floors but require more maintenance. The water must be kept very clean, or the fogging nozzles will be plugged in, so the filters should be checked or cleaned regularly or replaced as needed.

Cooling principles

Apply 0.05 inches of water on each cycle and spray the cows for a short time of 2 to 3 minutes; enough time to moisten the skin of the cows, but not so much that the water flows into the udder. Adjust the spring cycle length until you get the moisture you need. The air has to be forced into the cows with fans to cool the watered cows to evaporate. The fans should be ran continuously. Use evaporative cooling in free-stall barns, feeding barns, shady structures, holding areas, shaded areas, or any area covered with concrete floor. It is better to visit other existing installations in your area to see the systems that dairy farmers operate on before making a new cattle cooling system.

Designing principles

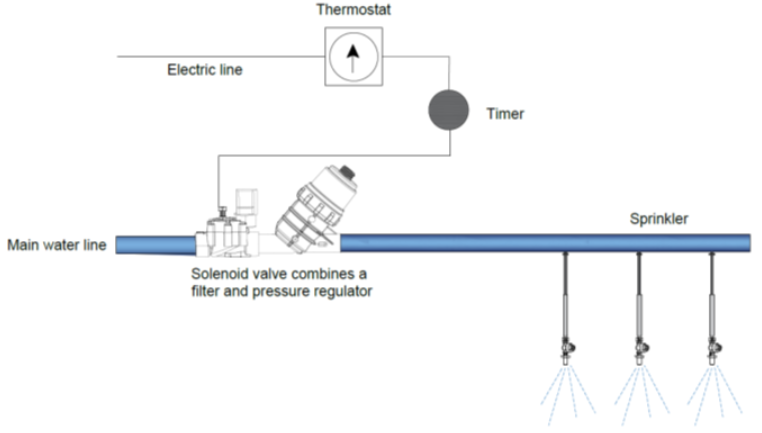

• Thermostat :

To control the sprinkler and fans; Sprinklers should be kept below 75 degrees F to prevent overheating and freezing. Fans should be operated throughout the night if the temperature does not fall below 70 F to allow the cows to lose their stagnant heat during the day.

• Timer :

15 minute adjustable to control the sprinkler cycle.

• Solenoid Valve :

To turn the water on and off.

• Pressure regulators :

The main pressure regulator can be installed at the beginning of the pipeline or smaller regulators on each sprinkler nozzle.

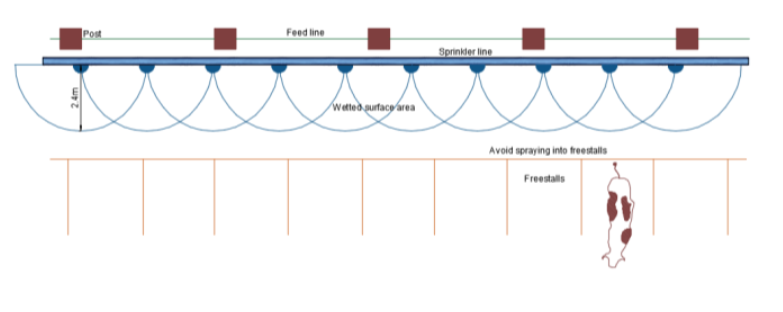

• Pipe size & Location :

Depending on the length and area of the sprinkler facility & the number of sprinklers and their flow rate, the height of the barn, posts or other attachment points, the width of the area to be sprayed, and the height at which fans can be placed. The pipe can be installed next to the feed area of a drive-through freestyle barn

• Sprinkler :

Using 180-degree nozzles, pour water into freestanding; In a spacious feeding area, 360-degree nozzles can be placed in the centre of the cow's space under the fans. They should be placed as high as possible so that other running cows do not hit the pipes and pass under the equipment, but the water does not hit the fans, or the fans do not blow water as it is low enough.

The type of nozzles or sprinklers depends on many factors and may differ for each application. Sprinklers should have a base of at least 1/2 inch. Choose a sprinkler with a spray radius that is appropriate for the water pressure you are using. Decide where sprinklers will be installed. You'll want a 180-degree pattern next to the feeding area. You might want a 360-degree pattern over a holding area. Next to the feeding area, 180-degree nozzles should be installed. 360-degree nozzles set in the middle of the cow alley in the same barn.

• Nozzle :

To get the appropriate spray pattern for each nozzle, you'll need to know your water pressure. Use nozzles in the right range. The number of nozzles on a pipeline, along with the water flow rate(gpm). Space the sprinklers as far apart as the radius of throw of each sprinkler once you've determined the correct spray pattern for your nozzles and water pressure. Sprinklers should be spaced every 2.4m radius. This results in a pattern of overlapping coverage. If the fans are set low, a flat or 5-degree trajectory is required to avoid spraying the fans and motors.

• Check Valve :

Check valves must be installed. Check valves can be used to prevent water from flowing back through the pipeline. When turned off, these are effective in preventing water from flowing out of the system.

Things to look out for when installing a fan

When picking fans, keep in mind that a fan built by a business that specialises in fans for livestock facilities will last longer in the harsh climate in which it will be used. Performance data from an impartial testing lab, such as BESS (Bio environmental and Structural Systems Laboratory), is best for comparisons. It's impossible to compare one fan to another without such unbiased information. Because these fans will not be running against a vacuum, airflow should be compared at 0.00" static pressure. Fans should be tilted so that they blow down to the floor directly under the next fan. A 48" fan with 1 hp motor delivers approximately twice as much air as a 36" fan (1/2 hp) and uses about twice as much power. It will not, however, throw air twice as far, so more power (and usually more initial cost) is needed to ventilate barns with 48" fans than 36" fans. Sometimes, pole spacing dictates the need for 48" fans. (It is usually easier to install fans on existing poles in the barn rather than hanging them from a high ceiling or rafters.) Otherwise, 36" fans are usually a better choice. A 36" fan that produces 11,000 cfm @ 20 cfm/watt and runs for 4,000 hours per year at $0.10 per kWh will cost $220 per year to operate. A 10% more efficient fan will save $660 per year in electrical expenditures if a barn has 30 of these fans.

Fans can be arranged in a variety of ways in barns. If necessary, fans can blow along lanes spaced according to the effective throw of the fan (usually 10 times its diameter) or diagonally across the barn. Fans can be arranged in a variety of ways in barns. If necessary, fans can blow along lanes spaced according to the effective throw of the fan or diagonally across the barn.

Fogging system

Only use this system in barns that are tall 3.6m at least, open-sided, and with a ridge vent. High-pressure fogger 200 psi systems have been shown to be as effective as fans and sprinklers in cooling cows. There must be enough fans and high-pressure foggers to cool the entire area. The fogger nozzles are attached to the fan's front. Instead of soaking the cow, these technologies chill the air. Water is sprayed into the air, vaporises, absorbs heat, and cools the air, which is then blown across the cow to cool her more efficiently. Pressure regulators and a high-pressure pump capable of 200 psi.

To avoid respiratory difficulties, ensure that the barn is properly aired. To avoid over-cooling, use a thermostat to turn off the foggers when the temperature drops below 78 degrees F. To prevent internal rainstorms and early rusting or rotting of the barn, the foggers run continually above 78 degrees from roughly 3 hours after dawn to 2 hours before sunset. Unless the temperature dips below 70 degrees F, fans should be turned on all night.

.png)

No comments yet