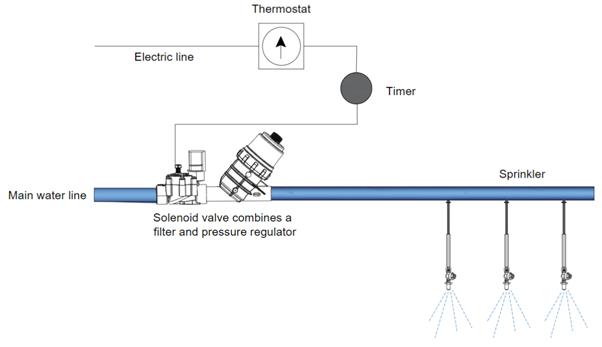

3. Water supply and delivery capacity

The

water supply system installed must be able to deliver sufficient water

at the design pressure throughout the sprinkling system and satisfy all

other farmstead water requirements (i.e., drinking water, parlor needs,

flush water, etc.) which occur simultaneously. Consider using a

reservoir system when the water supply flow rate is limited. A reservoir

system accumulates water during off periods.

4. Water Pressure

Normal operating pressures for low-pressure systems are between 1 and

1.4 Bar. Avoid excessive system pressures to eliminate the production of

very fine droplets that do not soak the hair coat, and may drift away

more easily in air currents. Consider installing a pressure regulator to

keep the water pressure within operating limits for the nozzles as

well.

5. Water in line filter

An

in line filter, usually a Y-filter with a flush valve and a 200 to 500

mesh screen, can be included in the system to protect nozzles from

plugging with rust particles and sand. It is important to check and

clean filters periodically.

6. Flushing and shutdown

Consider

providing a valve or removable plug at the end of each lateral to flush

sand and rust from the lines. Make sure that the system and all lines

can be drained prior to freezing weather condition.

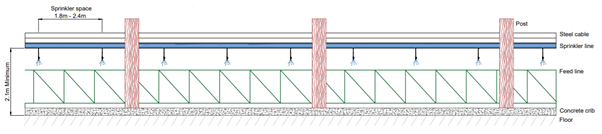

7. Distribution Pipe Selection

Various

types of plastic pipes PVC or polyethylene can be used for supply and

distribution lines. In addition to cost and ease of installation,

consider susceptibility to sunlight degradation, durability, and need

for mounting support.

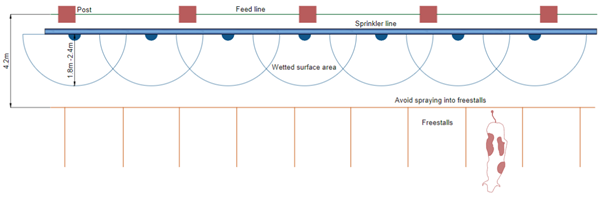

8. Pipe Sizing

Pipe

size requirements will depend on feed line length, number and length of

distribution branches, number of nozzles per branch, nozzle flow rates,

and number of branches on at one time. Water velocities should be

limited to 1.5m per second or less to avoid water-hammer problems. This

can be used to size distribution lines and supply line as well. The

supply line needs to be sized adequately to limit the pressure drop in

the line to 20% of the operating pressure. A factor, reduction

coefficient should be considered for reduced friction loss in pipes with

multiple outlets (i.e., nozzles in this case) due to reduce flow in the

pipe.

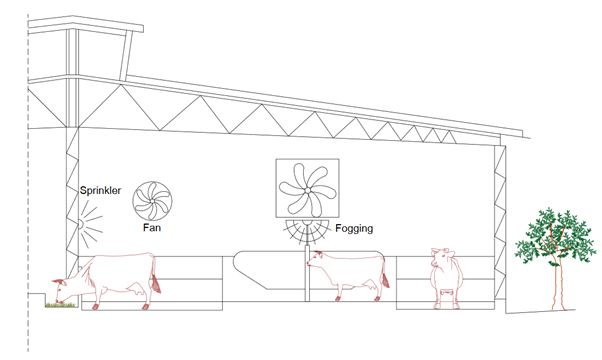

9. Fan selection and installation

Low

pressure sprinklers and fan cooling systems include mixing fans to

create a drift past or across the cows. Direct-drive axial-flow fans are

preferred, this is because they retain their performance over time

better than belt-driven fans. Most mixing fans are around 1m in diameter

and normally installed about 3m to 3.6m above the cow feeding alley, or

high enough to clear equipment operating below the fans.

Fans

over freestalls are usually mounted 2.4m above the cow alley or higher

if necessary to keep cows from reaching the fans. The fans are angled

downward at between 15 to 20 degrees. The goal is to create air

velocities around 5m/sec across the cow's backs. The recommended

distance between fans is 9m for 90cm diameter fans and 12m for 120cm

diameter fans. All fans should be blowing air in the same direction.

Most cooling fans seen in naturally ventilated barns are mounted to blow

air toward the East or North.

Management strategies that could be adopted against cold weather

Animals

must be provided proper bedding and warmth to protect them from extreme

cold, this can be achieved by various heating techniques. Heating

system include radiant, floor, air-make up and unit space heaters.

1. Radiant heating

Radiant

heaters work well for zone heating of young animals. Animals find

comfort by moving closer to or farther from the heater. Energy from a

radiant heater passes through air without warming it. When the energy

strikes an animal or any other surface, it is absorbed and object warms.

The warmed object then warms the air around it. Different types of radiant heaters are infrared heaters, heat lamps, gas catalytic radiant heaters etc.

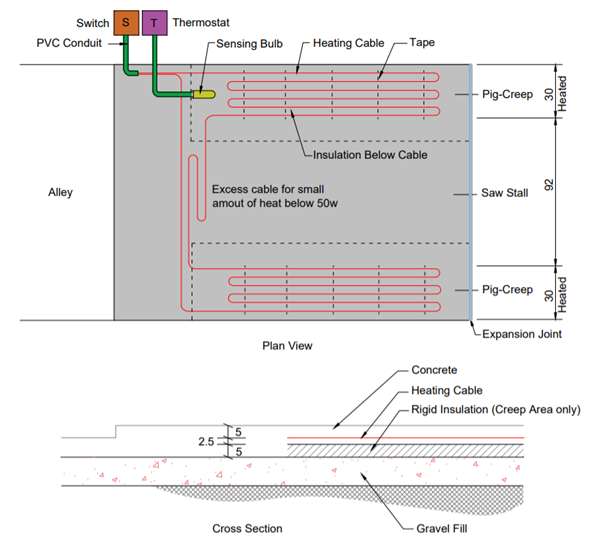

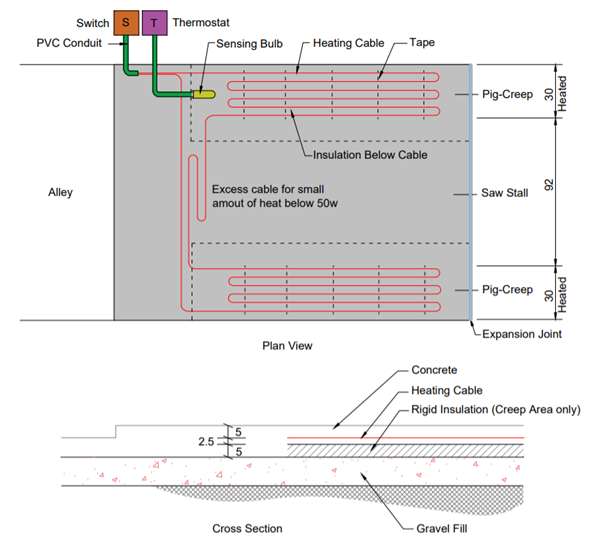

2. Floor heating

Floor

heating is primarily suggested for localized heating. Possible uses of

floor heating are in farm shops, small animal housing and other heated

work areas. Common floor heaters are electric resistance cables or hot

wire pipes which are buried in concrete. Floor heaters evaporate liquid

from the floor, which uses heat and increases the building relative

humidity. While designing a floor heat system care should be taken not

to setup too much heated area, because it might be not efficient and

lead to loss of heat. In addition to that, the heating area should not

be too less. This may encourage the animals to pile. For better heating

effect use waterproof insulating media under the floor, but not in

direct contact with the heating elements.

Fig.5 - Floor Heating

3. Space heating

Electric space heaters can be used for heating and warm the surrounding

air. Space heaters are heating devices which are designed to focus heat

in small zones. They work by blowing hot air through a

fan. This naturally rises and forces colder air to the floor. This

process helps to circulate the heat and warm the required space

effectively. Space heating is a fast and efficient method of heating as

it heats up the room air and maintain the room temperature.

No comments yet