Types of impellers in centrifugal pumps and applications

What is

What is an impeller in a centrifugal pump?

An impeller

is a rotating component of centrifugal pump with vanes or blades that

accelerates fluid outwards radially from centre of rotation. Impeller impart

energy to the fluid being pumped. It transfers mechanical energy from pump’s

drive to kinetic energy in fluid.

Most common type of impellers and application.

There are

three basic impeller designs. They are as follows:

Closed impellers

These types

of impellers have their vanes sandwiched between two solid circular plates. The

liquid travels through the channels between the plates. This design creates the

most efficient flow. The flow enters the impeller through centre and exits

through outer periphery of impeller. This is the most common type of impeller.

Application:

Mainly intended for liquid that are free of solid/suspended particles and less

viscous.

Semi-open Impellers

These

impellers have one side of vanes attached to a circular plate and other side is

exposed to the interior of pump housing. Instead of being sandwiched between

two plates, these impellers have one side open. This design is less efficient

than closed impeller, since the liquid is immediately interacting with rest of

fluid.

Application:

Mainly intended for liquid that has small amounts of solid/suspended particles

and more viscous.

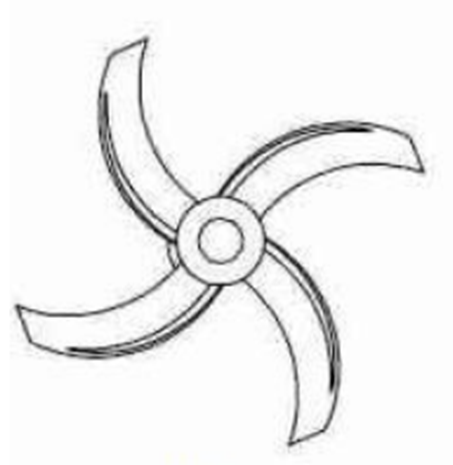

Open impellers

These

impellers have vanes that are open and are not enclosed by any plates. The

efficiency of these impellers are very less than that of the closed impeller.

This is due to the fact that, liquid flowing into pump casing interacts with

liquid that is already in the casing causing decrease in efficiency.

Application:

Pumps with these impellers are able to handle more suspended solids and viscous

liquid.

No comments yet